TTI’s Brand Portfolio

TTI is relentlessly focused on the continuous development and enhancement of cordless technology and groundbreaking product solutions throughout categories such as home improvement, repair, maintenance, construction, and infrastructure. Our diverse portfolio features renowned brands such as MILWAUKEE, RYOBI, and HOOVER, recognized as market leaders on a global scale.

Our pursuit of excellence has garnered international recognition for our products from various third-party entities, resulting in numerous product design and innovation awards. These accolades underscore our commitment to pushing the boundaries of innovation and serve as a testament to our ability to consistently deliver cutting-edge products.

Product Development Awards

20V Cordless Trim Router

Good Design Award Chicago

20V Hybrid LED Tripod Light

Good Design Award Chicago

M18 FUEL Compact Pipe Threader

- IDEA – Finalist

- German Design Award – Winner

MX FUEL Concrete Vibrator

iF Design Award – Finalist

40V HP Brushless

46cm Lawn Mower

German Design Award – Gold

ONEPWR CLEANSLATE Cordless Carpet & Upholstery Spot Cleaner

Better Homes & Gardens Clean House Awards 2022 – Best cleaner for pet messes

Leading the Industry Shift to Lithium-ion and Advancing Toward a More Sustainable Energy Source

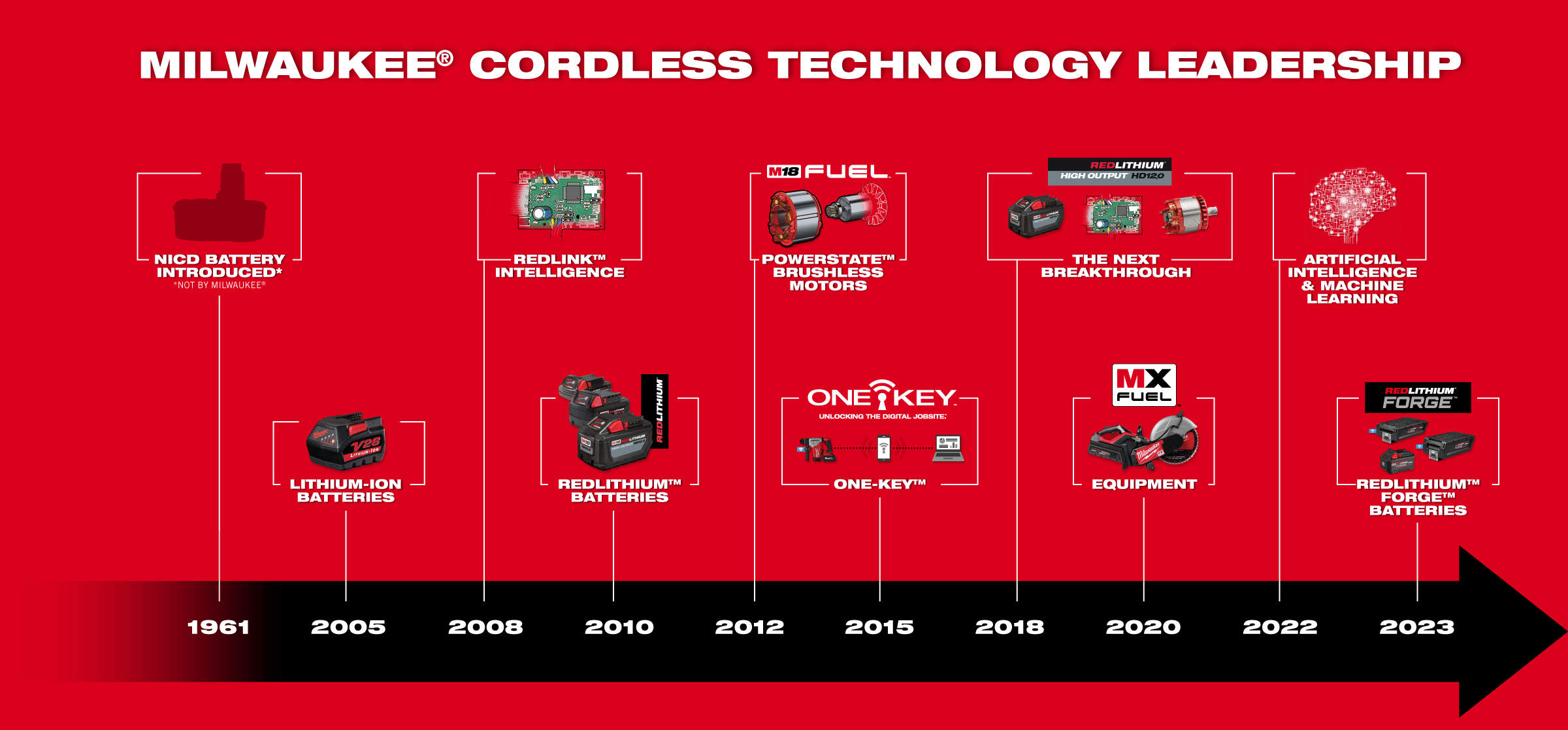

MILWAUKEE is committed to enhancing the safety and productivity of professionals in the trades, and this mission has paved the way to a series of groundbreaking industry “firsts.” These strides in innovation have not only empowered users, but they’ve also contributed significantly to lessening the overall environmental impact of power tool manufacturing, while simultaneously optimizing overall efficiencies.

From the breakthrough introduction of lithium-ion in 2005 that set the stage for transformative change, to the creation of MX FUEL, each step in this evolutionary journey reinforces MILWAUKEE’s status as an industry leader. It not only reshaped the trajectory of the power tool landscape, but also left an indelible mark on the industry’s environmental impact.

In the late 1990’s and early 2000’s, the power tool industry was comprised of corded or NiCd battery-operated tools. When MILWAUKEE pioneered the integration of lithium-ion technology in the power tool industry, the company fully invested in the shift. The following pages explore how this battery technology is revolutionizing the industry by distancing itself from inefficient NiCd battery technology and bridging the gap with the more environmentally friendly lithium-ion.

NiCd Batteries

- Inefficient

- Less energy dense

- Contains Cadmium

- Poor battery discharge

Li-ion Batteries

- Requires less raw materials

- More efficient

- More power dense

- More energy dense

- Longer cycle life

- Leads to more efficiencies & energy savings for the entire system

Overcoming NiCd Hurdles: The Solutions of Lithium-ion Technology

Battery Discharge

Short Term

The power output of a NiCd battery diminishes as it discharges or is actively used, leading to a decline in application speed and an inability to tackle demanding tasks effectively, resulting in a loss of productivity. This effect is not observed with lithium-ion batteries.

Medium Term (Memory Effect)

A NiCd battery demands maintenance in the form of additional charging, and a failure to achieve a full charge could potentially damage and shorten the battery’s lifespan. For users, this translates to a loss in productivity and additional costs incurred due to the need to replace damaged batteries. On an environmental note, it results in the disposal of more batteries. However, with MILWAUKEE’s implementation of electronic (digital) battery management in lithium-ion batteries, there is no memory effect, and these batteries can be partially charged at any time.

If you regularly discharge your NiCd battery partially and then recharge it, the battery will eventually “remember” this level and no longer be able to reach its full capacity.

Long Term (Cycle Life)

NiCd batteries have a limited cycle life, indicating the number of times they can be recharged. In contrast, MILWAUKEE lithium-ion batteries boast an impressive lifespan, significantly reducing the frequency of replacements.

Self-Discharge

NiCd batteries exhibit a self-discharge rate approximately three times higher than that of lithium-ion batteries. This implies a loss of charge over time, even when stored on a shelf and not in use. The consequence is more frequent charging, and due to the inherently limited charging cycles of NiCd batteries, it contributes to a higher volume of disposed batteries. In contrast, lithium-ion batteries feature an exceptionally low self-discharge rate, retaining their charge effectively. Unlike NiCd power tool batteries, a lithium-ion battery can be retrieved from the shelf after a 10-month hiatus without use and still function seamlessly.

Environmental

Removal of Toxic Heavy Metals

Cadmium, one of the most toxic heavy metals and carcinogenic, is a key component in NiCd batteries. In the environment, Cadmium is toxic to plants, animals and micro-organisms.

Reducing reliance on industrial use of heavy metals such as Cadmium in favor of more environmentally friendly technologies can help reduce the risks of contaminating soil as well as water, and cancer and birth defects.

TTI has partnered with Call2Recycle for over 20 years to ensure that our batteries and battery-powered products are responsibly recycled when they reach end-of-life.

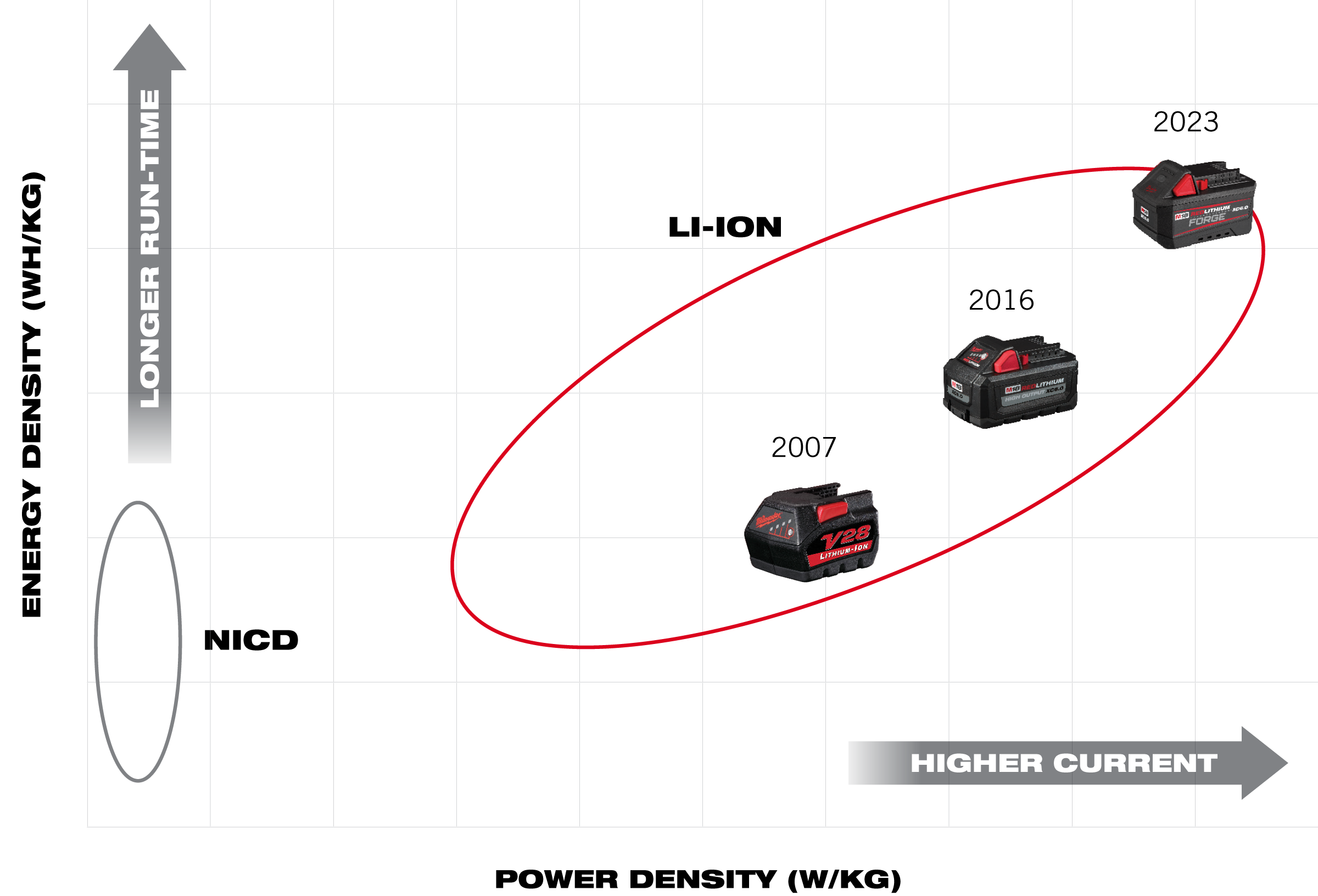

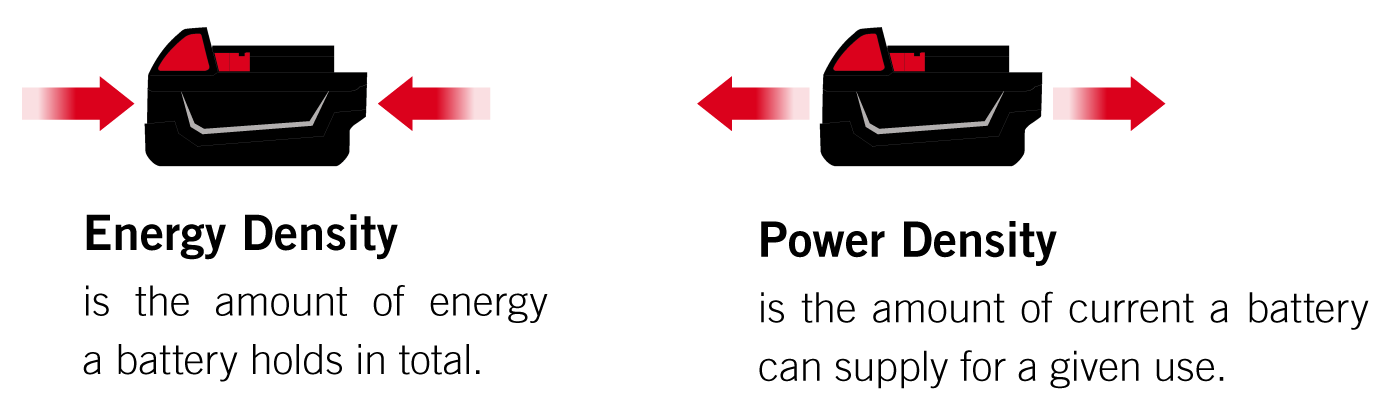

Power & Energy Density

Compared to NiCd batteries, lithium-ion exhibits a higher energy storage capacity per unit weight, reducing the need for as many raw materials to achieve equivalent battery life and performance. Furthermore, the superior energy density of lithium-ion translates to less frequent recharging compared to NiCd batteries. This, along with more power density through less internal resistance, gives users the ability to do more for longer. MILWAUKEE is at the forefront of advancing the industry by continually enhancing battery chemistry, mechanical design, and manufacturing processes, aiming to elevate power and energy density in lithium-ion batteries. This progress is achieved while ensuring compatibility with existing systems (M12, M18, MX FUEL), propelling the industry towards accomplishing more work per charge and replacing traditional corded, air and gas solutions.

Leveraging Lithium-ion Batteries: Unlocking Enhanced Efficiencies and Pioneering New Capabilities

The transition to lithium-ion batteries required the development of more efficient motors, advanced electronics, and sophisticated mechanisms within MILWAUKEE’s power tool solutions. Consequently, this technological evolution has given rise to unprecedented capabilities that were previously unseen in the industry.

More Efficient Mechanisms

When designing corded tools and their mechanisms, efficiency was not top of mind because AC energy was perceived as infinite. With the need to extend the battery life while meeting the expectations of power for tools like the M18 FUEL SUPER SAWZALL Reciprocating Saw, MILWAUKEE could not simply add a battery on the back end of the corded version. Instead, the design uses more efficient mechanisms to improve not only battery run-time but also size and weight. It even cuts faster than its corded predecessor.

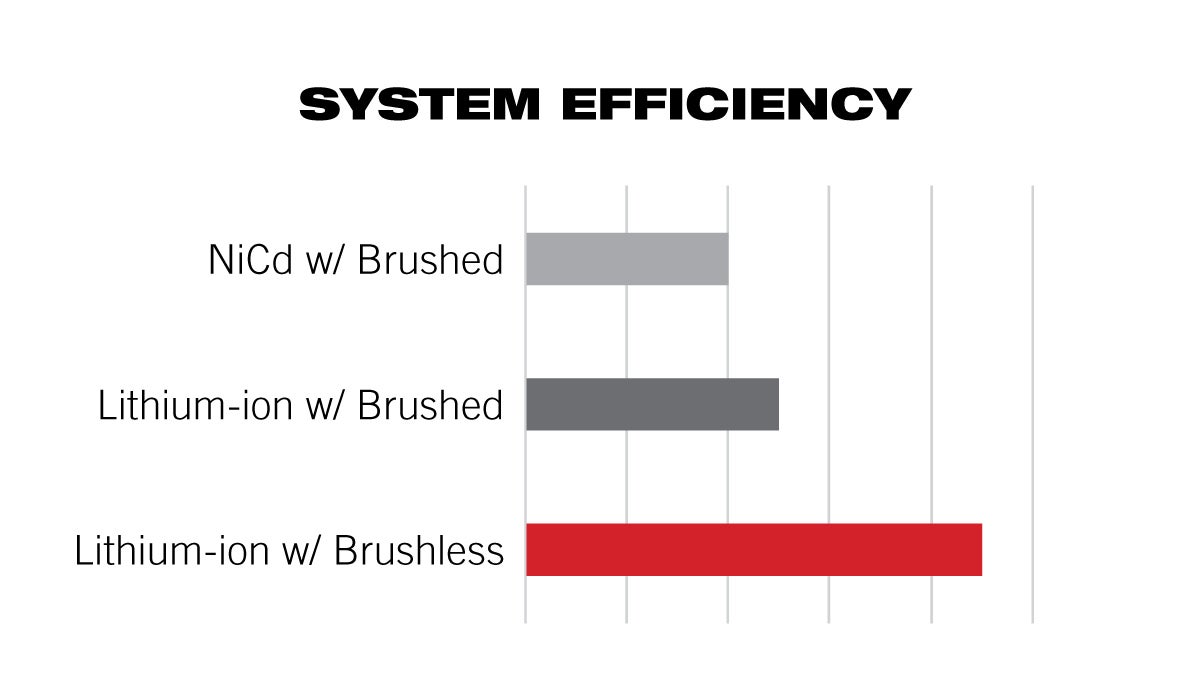

Brushless Motors

Brushless motors are more efficient than brushed motors. With a higher motor efficiency, there is less energy wasted through heat, allowing users to do more on a single battery charge. They have 10X longer life and require less maintenance than brushed motors. MILWAUKEE’s focus on brushless motors improves peak motor efficiency from 80% to over 90%.

More Efficient Electronics

Lithium-ion batteries are well-suited for integration with advanced electronics and digital battery management systems. A digital microprocessor is required to manage all aspects of the lithium-ion battery, including charge control, discharge control and temperature. This allows for more precise control over the battery’s performance, contributing to increased efficiency and safety.

Did You Know?

MILWAUKEE worked with the U.S. Environmental Protection Agency (EPA) to help develop the first Energy Star program for battery chargers. This foundational work was the catalyst for the development of meaningful battery charger efficiency requirements, culminating with the publication of federal efficiency requirements by the U.S. Department of Energy

Technology That Leads to Real World Benefits

By integrating the most advanced lithium-ion batteries with state-of-the-art brushless motors and the world’s most capable electronics packages, users can truly push the boundaries of cordless performance, unlocking a realm of enhanced productivity and safety beyond what was ever available through NiCd, corded, gas or pneumatic tools. Moreover, users will have cordless battery systems that are compatible with the extensive array of work they do – everything from pouring and finishing concrete indoors to the delicate removal of spot welds from car panels.

By ensuring backward compatibility, we not only protect the user’s investment into their systems but also safeguard against the potential obsolescence of tools when transitioning to new technology

Corded to Cordless

The advancement of lithium-ion within the power tool industry has led to opportunities to challenge conventional wisdom on what types of tools can be effective cordless solutions. These advancements have led to solutions that deliver true corded performance, often times rivaling the power and efficiencies that could be delivered through an outlet. The continued focus on furthering the technologies of batteries, motors and electronics enables the ability to exceed the performance expectations of “power-hungry” tools while also delivering on the run-time and ergonomics needs of the users.

Solving the Pneumatic Dilemma

Pneumatic requires significantly more material, expense, and energy to perform the work while also creating safety hazards (trips, accessibility, noise) for users. Whether working with impact wrenches, ratchets, polishers, band files, or tire buffers in the shop, or nailers out on the site, MILWAUKEE provides solutions to “cut the hose” and address the inefficiencies that accompany pneumatic.

Conquering Frustrations of Gas

MILWAUKEE has nearly two decades of leadership in integrating advanced lithium-ion technology with motors and electronics. We’re now leveraging these core competencies to address issues in the equipment market, and landscaping and tree care.

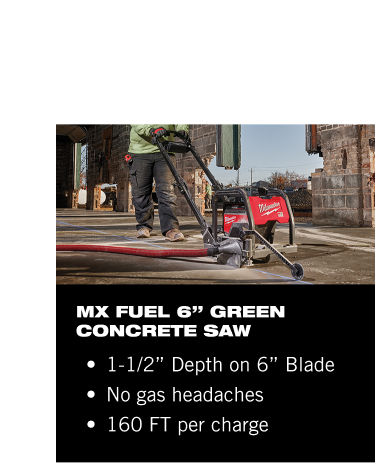

MX FUEL, a revolutionary battery-powered light equipment system, stands as a beacon in the quest to curtail carbon emissions and elevate battery-powered performance.

Meanwhile, the M18 Battery platform is helping to remove the frustrations of gas that landscape maintenance and tree care professionals have been feeling for years all while still delivering the power needed to complete the work.

Safety Solutions

Reduced Emissions

Our MILWAUKEE MX FUEL platform not only provides all the power of corded and gas-powered light equipment, but also produces no CO2 or exhaust emissions*. With the reduction of fumes and emissions, this platform is equipped with enhanced safety and sustainability for end-users. Harmful fumes, noise, and vibrations associated with the running of typical light equipment are reduced with this platform. This allows users to work indoors, in trenches, in tunnels, or even in mines without any gas headaches – vastly improving productivity. This system not only saves the end user time with refueling and starting up but also provides a cost savings on gas consumption and engine maintenance.

Fuel Savings

The cost of operating battery-powered equipment is more cost efficient than the cost of operating gas equipment, the same way an electric vehicle is more cost efficient to run than a gas-powered vehicle.

Maintenance Savings

Between fuel and maintenance, gas-powered equipment typically is more costly. These tools have numerous components that are prone to failure, such as spark plugs, fuel filters, carburetors, air filters, drive belts, and starter cords. Additionally, there are various potential issues surrounding fuel mixing for 2-stroke engines, including the risk of missing the exact ratio and forgetting to add engine oil, all of which can result in significant expenses.

Alternatively, MX FUEL is powered by a POWERSTATE brushless electric motor. The electric motors do not require a lot of maintenance, as they have very few wearable parts compared to a gas engine and there is less risk of improper use and maintenance.

Health

With no CO2 or exhaust emissions during use, MX FUEL products allow users to operate in spaces where operating gas-powered equivalent products pose harmful health risks.

Safety

The presence of gas on a jobsite poses significant safety concerns and can consume both time and money, given the special requirements for its storage and transportation. It is never 100% safe to have highly flammable gas on the jobsite.

Productivity

One of the biggest user frustrations is spending time setting up without cutting or breaking anything. Filling up a gas cut-off saw can be a time-consuming process, especially when compared to the speed and ease of inserting a battery, pressing the start button, pulling the trigger, and getting ready to cut.

*While in use

†When product is in use

Relentless Safety Solutions, Built for Productivity

We are unwavering in our commitment to deliver Relentless Safety Solutions, Built For Productivity.

MILWAUKEE is a world leader in jobsite solutions and has a long tradition of improving the safety of users through product innovation. We have dedicated resources to work alongside our users and partners to understand the demands of a constantly changing jobsite and how we can best deliver solutions to help them work safely and more productively.

Air Quality

Gas equipment is largely present on today’s jobsite. As a result, tradespeople are twice as likely to develop respiratory diseases due to exposure and inhalation of gas fumes and emissions.† We are dedicated to providing users with cordless solutions on our M18 and MX FUEL systems that eliminate exposures associated with gas equipment. Featuring advanced safety technology, the battery-powered MX FUEL 14” Cut-Off Saw w/ RAPIDSTOP is an example of our focus and dedication. This new cut off saw eliminates gas emission concerns and is safe to use both indoors and outdoors. The MX FUEL 14” Cut-Off Saw w/ RAPIDSTOP has the power of a gas-powered unit, with the ability to take on demanding applications such as cutting reinforced concrete and steel pipe. A push button start allows users to start the cut off saw in seconds, eliminating the strenuous, repetitive motions of priming, choking, and pulling the engine to start. By continuously innovating in cordless technology and expanding our M18 FUEL and MX FUEL solutions, we are on a mission to make gas tools and equipment a thing of the past. Our cordless solutions deliver upon the performance, run-time, and durability demanded by users without the hazards associated with emissions, noise, vibrations, and frustrations of gas maintenance.

† “Chart Book (6th edition): Occupational Diseases – Respiratory Diseases in the Construction Industry”, The Center for Construction Research and Training (https://www.cpwr.com/wp-content/uploads/publications/The_6th_Edition_Construction_eChart_Book.pdf)

Safety Technology

Each time power tools and equipment are used on the jobsite, bind-ups, operator errors, and drops are possible. MILWAUKEE is dedicated to designing power tools and equipment solutions that enhance the safety of users. Our leadership in batteries, motors, and electronics expands the capability of common power tool and equipment solutions to provide users with features that enhance safety; like AUTOSTOP control, which stops a tool when a bind-up is detected, and RAPIDSTOP brake, which quickly stops the tool. The MILWAUKEE M18 FUEL Dual Trigger Braking Grinder features all of these advancements with additional control provided through dual trigger activation, and a permanent side handle. This is the first time MILWAUKEE’s AUTOSTOP kickback control is included in an angle grinder, helping to reduce the risk of severe kickback during demanding applications.

Dust Management

Our MILWAUKEE business is committed to providing safe and versatile silica dust management solutions that help customers comply with the OSHA regulation on respirable crystalline silica dust (29 CFR 1926.1153). Our dust management solutions are focused on enhancing productivity. From the most universal dust extraction solutions fitting all major brands to a full range of products for floor-to-ceiling dust management, this is compliance made simple.

Vibration and Noise Reductions

Hand-arm vibration syndrome (HAVS) and noise-induced hearing loss continue to affect tradespeople across various jobsites due to repeated exposure. We are committed to delivering user solutions that reduce noise and vibration exposure. Solutions like the MILWAUKEE ROLL-ON 7200/3600W Power Supply remove loud gas-operated generators from jobsites and allows users to operate indoors.

Ergonomics

In order to combat musculoskeletal disorders (MSDs), MILWAUKEE is committed to ensuring ergonomics is a key aspect of our product development process. Our evidence-based approach to ergonomics and commitment to replacing manual applications with battery-powered solutions deliver products like the M12 Brushless Pruning Shears. With the integration of the M12 brushless technology and a slim ergonomic design, muscle effort is reduced by 75% compared to manual solutions, helping users complete the toughest applications with ease and speed.

Visibility

MILWAUKEE site lighting is the industry’s first system of high-output LED lights to offer full-day runtime in portable packages. The site lights use the most advanced lighting technology to deliver a consistent beam, optimized color temperature, and true representation of colors and detail leading to a more productive work area. Our jobsite lights shine brighter, last longer and are uniquely designed to adapt, perform, and survive the daily demands of professional use.

Personal Protective Equipment

We are dedicated to keeping our users safe and productive on the jobsite. personal protective equipment has seen little innovation over the years, driving users to modify their gear to better meet their needs. We have taken the time to understand our users’ needs and develop PPE from the ground up, delivering head protection that allows users to adapt to each job and safety glasses that can be worn all day with lasting fog-free lenses. MILWAUKEE is focused on creating innovative solutions that won’t slow users down, helping them stay safe and stay productive on the jobsite.

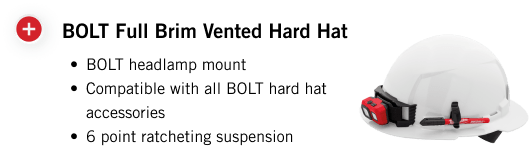

OSHA switches to safety helmets to better protect agency employees, MILWAUKEE comes out on top as the brand of choice

In a groundbreaking development for workplace safety, the Occupational Safety and Health Administration (OSHA) agency employees officially shifted from traditional hard hats to safety helmets on December 11, 2023, marking a pivotal moment not only for our MILWAUKEE brand but also for the safety of the construction industry. Injuries from slips, trips, and falls are some of the most common and can result in oblique impact forces being passed to the brain. These oblique impacts can cause Traumatic Brain Injuries (TBIs). OSHA cites the advancements in design, materials, and protective features that help to protect the workers’ entire heads as some of the main reasons for their shift to helmets.

After a rigorous selection and testing process, mandated by government protocols, MILWAUKEE’s helmet was selected from three different brands that were put to the test. MILWAUKEE is honored to be the chosen brand of helmets for all 1,100 CSHO employees of the DOL-OSHA, a unanimous decision that underscores our commitment to user safety and productivity. This earned achievement positions our helmets at the forefront of safety for trade professionals nationwide each day.

Our Type 2, Front Brim Safety Helmets deliver users better protection and more comfort. As part of the BOLT network, these helmets allow users to easily integrate additional personal protection equipment and accessories so they can secure accessories simultaneously. Our BOLT Safety Helmets also offer protection from top and side impacts.

SMARTWASH Technology

The World’s First Cordless Carpet Cleaner

HOOVER’s ONEPWR battery system delivers energy efficient cleaning products without compromising power or performance. The HOOVER ONEPWR SMARTWASH Cordless Carpet Cleaner brings an energy efficient option to the carpet cleaning market with an untethered, powerful deep clean.

The ONEPWR SMARTWASH is engineered with high efficiency motors that provide the same cleaning performance with up to 6X less power consumption than corded options. Our triggerless design automatically cleans as you move, providing a convenient cleaning experience.

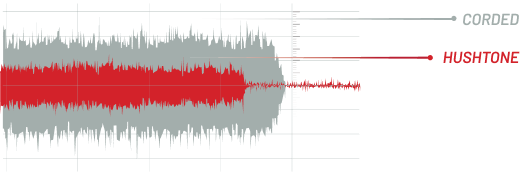

Products with HOOVER HUSHTONE technology are engineered to provide a quieter clean without compromising performance. This offers users a more convenient, less disruptive way to clean. With only an 83 dBA noise rating, our products with HUSHTONE technology have the ability to operate at a much quieter capacity than the competition.

Features

- Cleans as you move with Automatic Cleaning Technology

- Full-Size capacity in a compact footprint thanks to TruMAX Technology

- SPOT Mode for deep set-in stains

- DRY ONLY Mode for fast dry time

- Customize your clean with interchangeable Brush Rolls

- Premium LED display to continuously monitor the status of your machine

Convenience

- Over 31% smaller in size, saving the user space in their home.

- Over 39% reduction in usage weight

Safety

- Absence of cord reduces the potential for a safety hazard

- No hazardous voltages while operating a product with water

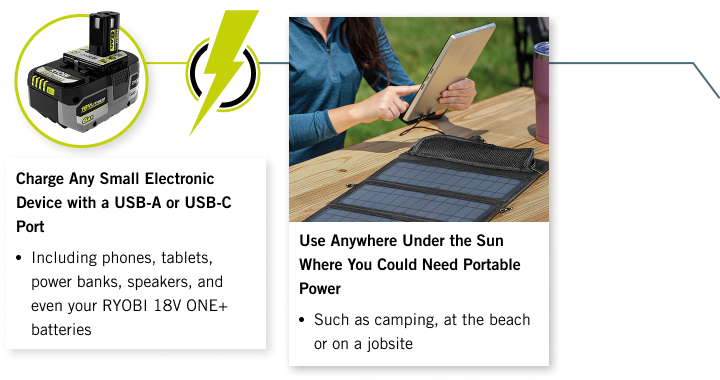

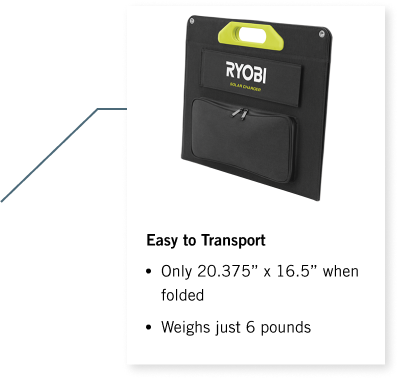

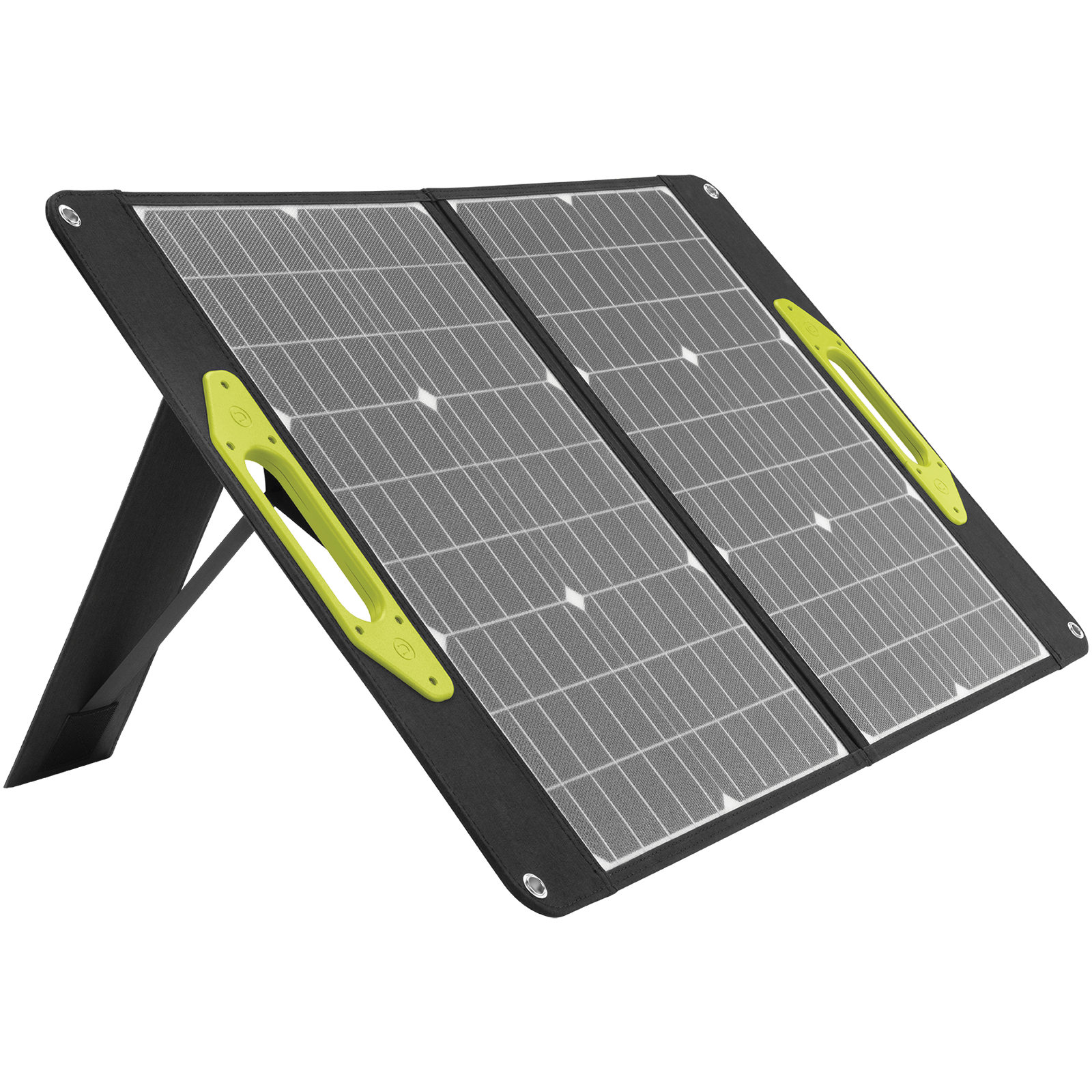

The RYOBI 60 Watt Foldable Solar Panel powers any small electronic device with a USB-A or USB-C port directly from the sun. For added compatibility, it also powers a variety of other electronics with the barrel plug connector and adaptors. It is ideal for powering your phones, tablets, power banks, speakers, and even your RYOBI 18V ONE+ batteries when combined with a compatible RYOBI power source. Pair with the RYOBI 18V ONE+ RYi818BG Power Station to charge up to 8 batteries consecutively using solar power.

This Solar Panel can charge a RYOBI 18V ONE+ 2Ah battery in under 1 hour and your phone in as little as 1 hour and 15 minutes. The compact, foldable design makes storing and transporting easy, so you can take it with you to charge devices when camping, on a jobsite and anywhere under the sun where you’d need portable power. Maximize the amount of light the panels capture using the freely adjustable kickstand or the (4) secure grommets.

Pair with Select RYOBI Inverters to Charge 18V ONE+ Batteries

Charge Your Phone in as little as 1 Hour and 15 Minutes*

Specs

USB-A Output:24W Max

USB-C Output:45W Max

Barrel Plug Output:59W Max

Barrel Plug Connector:5.5 x 2.1 mm

Adaptor Sizes:3.5 x 1.35 mm, 5.5 x 2.5 mm, 7.9 x 5.5 mm

*Sunlight and phone size may affect charge time.

Sustainable Products

As leaders in the cordless revolution, we remain dedicated to the development of sustainable products that are superior in power, energy efficiency, and safety.

- Promote circular business models by increasing service, repair, maintenance, refurbishment, and recycling services

- Increase investment in clean technologies

- Develop innovative products that improve living and working environments

- Developing an internal Life Cycle Assessment (LCA) process

- Increasing recycling efforts

| RISKS | OPPORTUNITIES | RESPONSES |

|---|---|---|

|

|

|

|

|

|

|

|

|